![]()

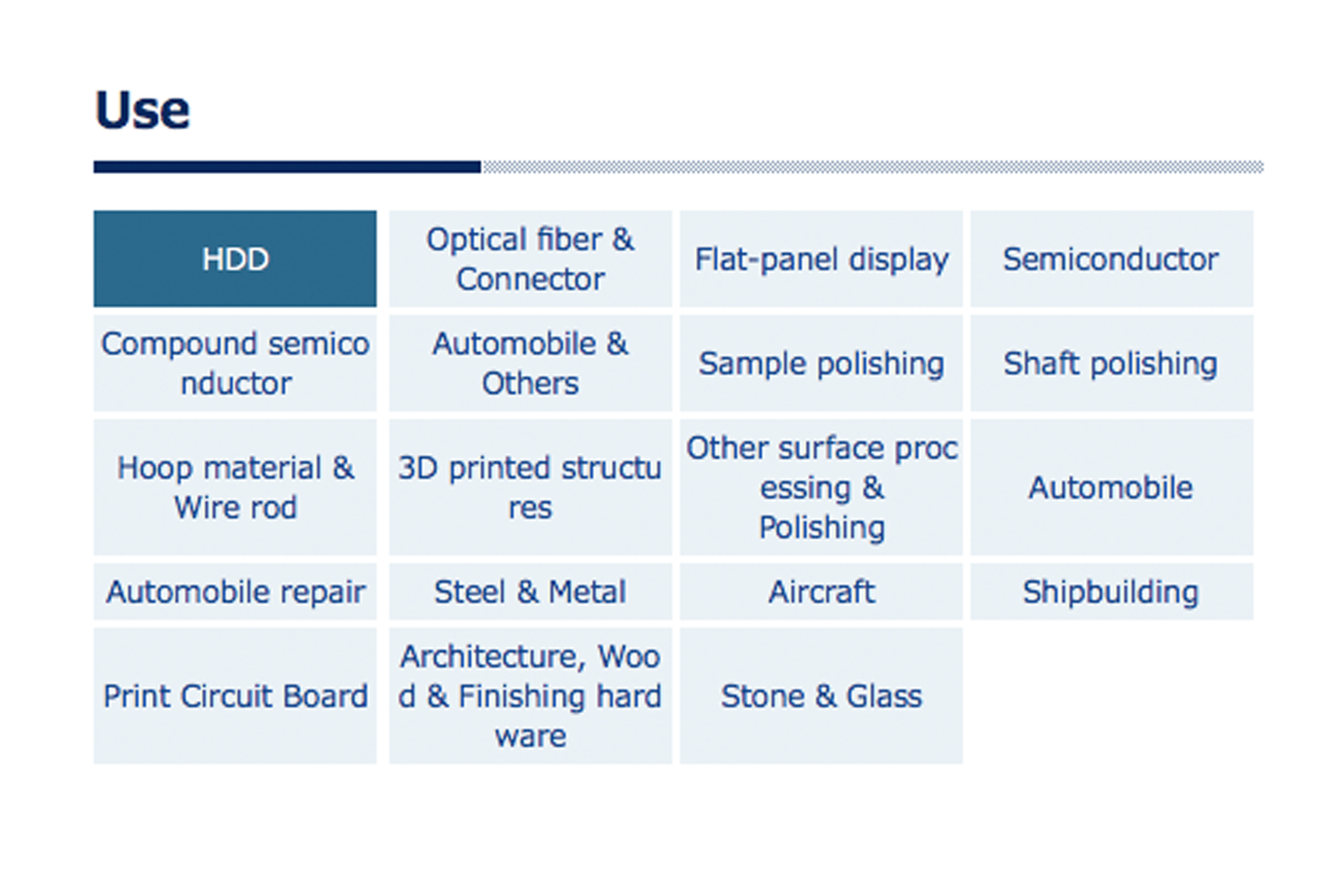

Liquid Polishing Slurry

Characteristic

Our optical fiber polishing slurry is available in various abrasive materials with a variety of lineups, which can be used for single core, multiple leads, any type of connector.

Moreover, it is possible to obtain higher performance from combination of various support pads.

Compound Semiconductor

Characteristic

High performance is demonstrated in finish polishing process of compound semiconductors. We customize and provide final polishing slurry using other silica and alumina abrasive grains. Conventionally, final polishing is carried out by using polishing slurry and a polishing pad, but in our polishing method, the use of a nano-level ultra-fine particle diamond slurry removes the need of using a polishing pad and still allows nano-level finishing.

We can also provide the finishing slurry of the silica, aluminum.

We can also provide the finishing slurry of the silica, aluminum.

026Ultimas

(Final Polishing Film

For final polishing

Characteristic

The Ultimas series was developed for the purpose of short polishing and high durability.

Excellent cost performance is demonstrated, usage at home and abroad has been increasing year by year.

In addition, we developed “Ultimas PRO” which gives the conventional exposure function of the fiber.

With conventional Ultimas you can finish the fiber height in the plus region after polishing which Ultimas was not good at.

Excellent cost performance is demonstrated, usage at home and abroad has been increasing year by year.

In addition, we developed “Ultimas PRO” which gives the conventional exposure function of the fiber.

With conventional Ultimas you can finish the fiber height in the plus region after polishing which Ultimas was not good at.

Diamond Paste

Characteristic

Uses high quality diamond powder.

High dispersion makes extremely specular surface and well polishing efficiensy.

High dispersion makes extremely specular surface and well polishing efficiensy.